Our company is located at the northeast of Wuxi, Jiangsu Province,

with only 2.5 hours of driving distance to Shanghai Pudong

International Airport, and the traffic is very convenient.

Wuxi Huadong Industrial Furnace Co., Ltd is a comprehensive

enterprise integrating scientific research & development,

engineering designing, system integration, equipment installation

and sales & services. Our company is dedicated to professional

manufacture the production lines for casting of various non-ferrous

metals and heat treatment since 1989.

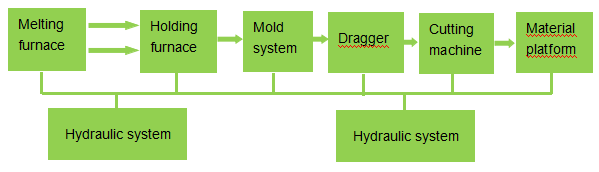

The production lines for casting non-ferrous metals

supplied by our company is complete in categories, specifications

and types, mainly capable of casting metals including copper and

copper alloys, also related to non-ferrous metals such as

magnesium, aluminum and zinc etc. The casting modes include

horizontal continuous casting, vertical casting and upward casting;

By using our production lines, customers can get billet products

with sections of near-the-net-shape dimensions and shapes,

including 8 major categories i.e. plates, strips, rods, foils,

tubes, bars and shapes. Heat treatment equipments include multiple

types of electric resistance furnaces or combination, such as well

type, box type, bogie-hearth type, bell type, protective-atmosphere

type, vacuum bright type, strong-convection circulation type etc.

For casting production lines and heat-treatment equipments, our

company can also provide various types of spare parts (furnace

shells, melting grooves, water jackets, iron cores, crystallizers,

special refractory, temperature measurement devices, transformers,

reactors, electric resistance heating elements, and mechanical

parts etc.); Our company can also provide cold-processing

equipments such as drawing mills and cold-rolling mills for tubes,

rods and shapes, as well as scrap metal balers etc.

Our company can develop, design, and manufacture

equipments for specific production lines according to customers'

requirements, provide complete services of solutions; Committed to

quality, quality priority covers the whole process of designing,

purchasing ,manufacturing, production, installation and after-sales

services etc. We are doing our best to realized most advanced in

technology, most reasonable in configuration, most superior in

quality, and most inexpensive in cost. We strictly follow the

requirements of ISO9000 quality system, achieving first-class

product quality.

Choosing Wuxi Huadong Electric Industrial Furnace Co. ,Ltd as the

partner means choosing trust and guarantee, and the correction

choice is the safeguard for the smooth operation of your

undertakings and reliable return of your investment.

Wuxi East China Furnace Co. ,Ltd would like to

cordially welcome friends from home and abroad for visiting and

guidance.